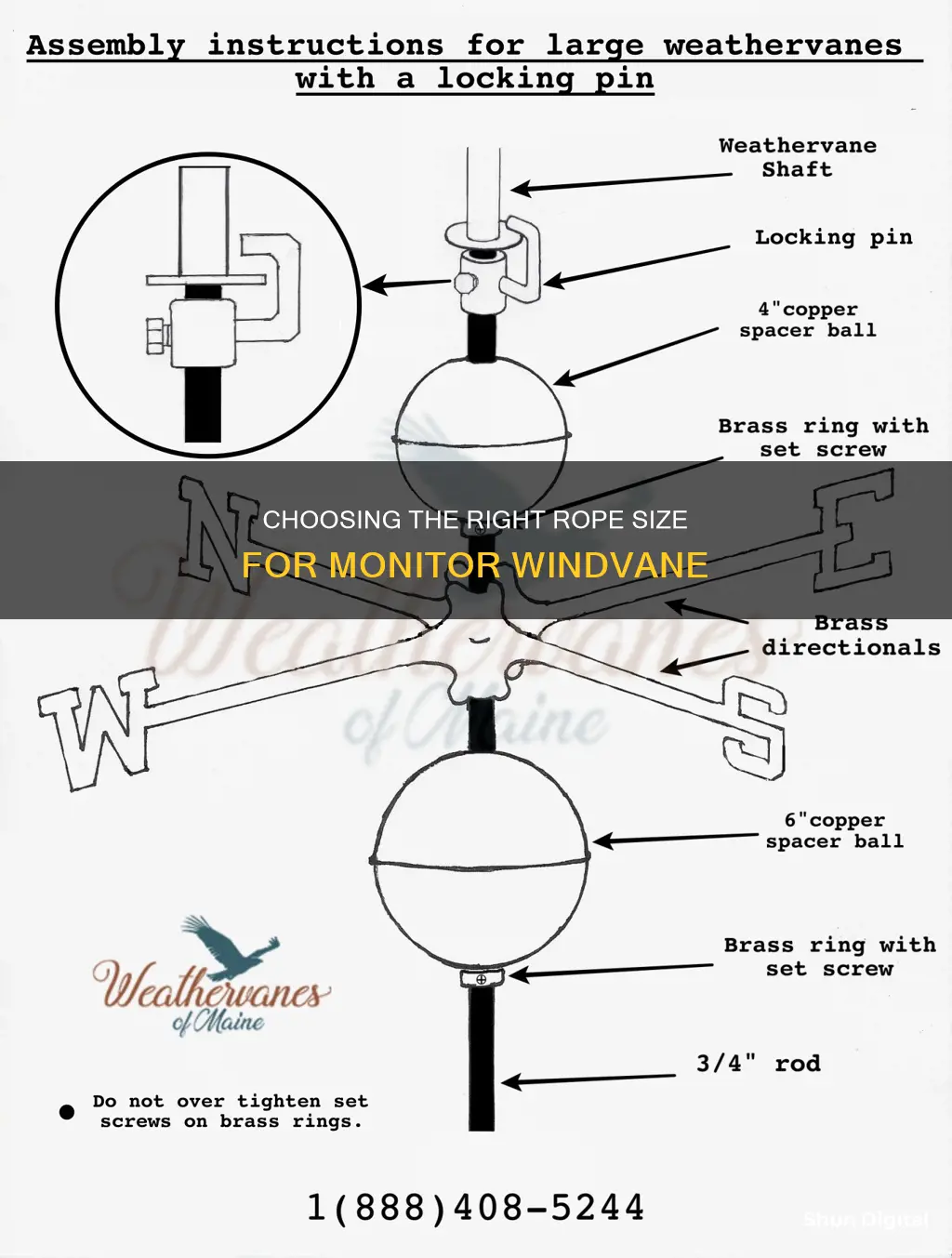

The Monitor windvane is a mechanical self-steering device for sailboats, which uses wind power to steer a vessel 24/7 without the need for electricity. The device consists of an airvane, connecting rod and gear linkage, and a paddle. When the boat wanders off course, the airvane's motion works with the gear to push the paddle, which is connected to the sailboat's wheel with lines, bringing the boat back on course. The optimum rope for the control lines of a windvane is one that is non-stretch, flexible, lightweight, and low-friction. Various types of ropes can be used, including Dyneema Ocean 12, Usacord double braid, and Spectra.

What You'll Learn

Optimum rope characteristics

The optimum rope for a Monitor windvane will be non-stretch, flexible enough to go around the blocks, and low weight/friction. While the breaking strain is not a concern, the rope should be strong enough to handle the load. It should also be easy to splice and have low stretch, flexibility, and slipperiness.

For the control lines on a Fleming windvane steering system, 8mm double braid rope can be used, but it stretches a lot on longer passages and needs regular adjustment. A 6mm double braid would be more than adequate and won't stretch as much. If you want to reduce friction and bulk, consider using a thinner rope like 4mm or 3mm Dyneema Ocean 12, which has a breaking strain of about 2 tons and is incredibly light, flexible, and easy to splice. However, keep in mind that Dyneema may not be suitable if you need to apply significant tension by hand.

For a Monitor windvane, Scanmar offers custom-designed Dyneema pendulum lines as part of their standard package. Dyneema is known for its strength and low stretch, making it a good choice for this application.

Monitoring Data Usage on Your iPad: A Guide

You may want to see also

Rope size and stretch

When selecting a rope for a wind vane, it is important to consider the rope's stretchability, flexibility, weight, and friction. While 8mm double braid rope is a common choice for control lines, it tends to stretch a lot on longer passages and requires frequent adjustments. To address this issue, some sailors opt for non-stretch alternatives like Dyneema Ocean 12, a single braid dyneema rope. This type of rope has a higher breaking strain and is lighter, more flexible, and less stretchy than double braid options.

Dyneema Ocean 12, with its low stretch properties, can enhance the performance of your wind vane by providing a more consistent connection between the control lines and the tiller. This is especially advantageous for longer passages where rope stretch can accumulate, leading to reduced control precision. Additionally, its flexibility allows for smooth movement around blocks and other hardware, ensuring efficient power transmission.

However, one drawback of Dyneema Ocean 12 is its slipperiness, which can make it challenging to secure with knots or cleats. To address this, sailors often splice loops into each tiller end and use lashing to make final adjustments. This technique ensures a secure connection while maintaining the benefits of low stretch and flexibility.

When selecting a rope size, it's important to consider the specific application and the amount of tension required. For example, if significant tension needs to be applied by hand, a thicker rope or a combination of Dyneema with a tail of double braid might be more suitable. On the other hand, if the goal is to reduce friction and bulk, a smaller diameter rope like 3mm or 4mm Dyneema can be a better choice. Ultimately, the optimal rope size depends on the specific requirements of your wind vane setup.

Monitoring Memory Usage: Tips and Tricks for Developers

You may want to see also

Rope flexibility and friction

Flexibility is a key trend in the wire rope industry, as it is for crane manufacturers. A smaller rope diameter means smaller sheaves and drums, resulting in a smaller and more competitive crane design. To achieve this, crane designers seek ropes with high breaking forces. Ropes with compacted strands, steel cores, and/or compacting of the entire rope provide high breaking forces and resistance to abrasion. Additionally, ropes consisting of many single wires increase flexibility and bending resistance.

Friction is the resistance to motion that occurs when two objects come into contact. In a rescue operation, for example, friction is essential for controlling the descent of a litter through a brake bar rack or while rappelling. When raising a load, however, friction becomes the enemy as it resists movement and steals energy. The angle at which the rope encounters objects also affects friction levels; for instance, a 90-degree bend over a building edge can double the force needed to raise a load.

The energy consumed by friction is converted into heat, and the smaller the objects generating friction, the hotter they become. This is because smaller objects have less mass to absorb the heat and less surface area to dissipate it.

When selecting a rope for a monitor windvane, it is crucial to consider both flexibility and friction. A flexible rope will be easier to work with and manoeuvre around blocks and other components. At the same time, understanding and managing friction will help control the movement of the windvane and conserve energy during operation.

Monitor Internet Usage: A Guide to Program WRT

You may want to see also

Rope strength and weight

Rope strength is the approximate average for new rope tested under ASTM test method D-6268. The tensile strength of a rope is the average strength of a new rope under laboratory conditions. This is determined by wrapping the rope around two large-diameter capstans and slowly adding tension to the line until it breaks. The tensile strength of a rope can be expected to decrease over time due to age, wear, sunlight exposure, splices, and knots.

The working load of a rope is determined by taking the tensile strength and dividing it by a factor that reflects the maximum load that should be applied to a given rope to ensure a comfortable safety margin before it reaches its breaking point. The working load for most kinds of rope is between 15% and 25% of the tensile strength. When a knot is tied in a rope, its tensile strength is effectively halved.

The optimum rope for a monitor windvane will be non-stretch, flexible enough to go around the blocks, and low weight/friction. A rope with a diameter of 3mm-8mm can be used for a windvane, with the smaller diameter giving increased flexibility. A 4mm Dyneema rope has a breaking strain of about 2t, while a 3mm rope has a breaking strain of 1.1t and is plenty strong enough. A 5mm Spectra rope can also be used.

Monitoring Data Usage: A Guide for Linksys Routers

You may want to see also

Rope material and maintenance

When selecting a rope for a Monitor Windvane, it is important to consider the rope's material and maintenance needs to ensure optimal performance and longevity. Here are some key factors to keep in mind:

The ideal rope for a Monitor Windvane should be non-stretch, flexible, lightweight, and have low friction. This ensures smooth and efficient operation of the windvane steering system. Some rope materials that are commonly used include double braid, Spectra, and Dyneema. For example, the Dyneema Ocean 12, a single braid Dyneema rope, is known for its high breaking strain, flexibility, and ease of splicing. However, it may not be suitable if significant tension needs to be applied by hand.

Maintenance of the rope is also important. Over time, the rope may stretch and require regular adjustments, especially on longer passages. It is recommended to inspect the rope periodically and make the necessary adjustments to ensure optimal performance. Additionally, keeping the rope clean and free from debris can help extend its lifespan.

When choosing a rope, it is advisable to consider the specific requirements of your Monitor Windvane and the conditions in which it will be used. Factors such as the size of the boat, the mounting system, and the expected weather conditions can influence the selection of the most suitable rope material and maintenance routine.

It is always a good idea to consult with experts or experienced sailors who can provide recommendations based on their knowledge and experience with different rope materials and maintenance techniques for Monitor Windvanes.

By selecting the right rope material and maintaining it properly, you can ensure the reliable and efficient performance of your Monitor Windvane steering system.

Understanding SRGB Mode on Your ASUS Monitor

You may want to see also

Frequently asked questions

The optimum rope for a Monitor windvane will be non-stretch, flexible enough to go around the blocks, and low weight/friction. While some sources suggest 8mm double braid rope, others recommend 5mm Spectra or 6mm double braid rope. Dyneema Ocean 12, a single braid dyneema rope, is another option that offers high strength, low stretch, flexibility, and ease of splicing.

When choosing the size of rope for a Monitor windvane, it is essential to consider factors such as stretch, flexibility, weight, friction, and ease of handling. Stretch and flexibility are important to ensure the rope can adapt to the movement of the windvane, while low weight and friction reduce resistance and improve efficiency. Additionally, consider the ease of handling, including the ability to splice and take tension when needed.

Some recommended ropes for a Monitor windvane include the following:

- 8mm double braid rope

- 5mm or 6mm Spectra rope

- Dyneema Ocean 12 (3mm or 4mm)

- Usacord double braid rope