Fujifilm is a Japanese multinational conglomerate headquartered in Tokyo, Japan, with operations in photography, optics, office and medical electronics, biotechnology, and chemicals. The company was established in 1934 as a manufacturer of photographic films and has since expanded its product line to include digital cameras, color films, color paper, photofinishing, and graphic arts equipment and materials. Fujifilm's camera manufacturing facilities are located in various countries, including Japan, China, the Philippines, Indonesia, and the United States. The company's commitment to quality and innovation has made it a trusted brand in the photography industry.

| Characteristics | Values |

|---|---|

| Country of origin | Japan |

| Headquarters | Tokyo, Japan |

| Manufacturing locations | Japan, China, the Philippines, Indonesia, the United States |

What You'll Learn

Fujifilm cameras are assembled in Japan, China, and the US

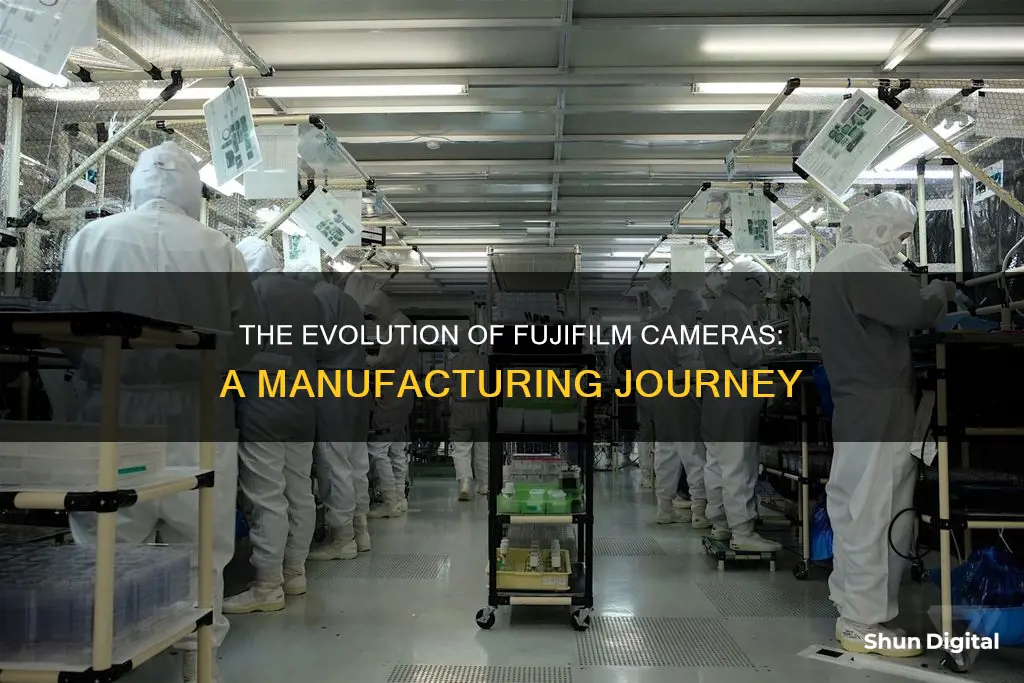

The Taiwa factory in Sendai, Japan, handles the final assembly of Fujifilm's most prestigious products, such as the X100 series, the X-Pro series, and the X-T series. The metal body of the camera is cast in another factory in Japan and then shipped to Taiwa for final assembly. Fujifilm's optics subsidiary turns raw materials into finished products, with factories in Japan and China dedicated to glass moulds, barrel processing, and lens polishing.

In the US, Fujifilm Manufacturing U.S.A., Inc., located in Greenwood, South Carolina, serves as one of the company's global manufacturing hubs. The complex includes state-of-the-art manufacturing facilities for the production of QuickSnap recyclable cameras, inkjet and conventional photographic paper, and digital printing plates.

Some models of Fujifilm cameras, such as the X-T4, are assembled exclusively in China, while others, like the X100V and X-Pro3, are listed as made in Japan. This diversification of assembly locations allows Fujifilm to balance cost reduction and quality control in different markets.

Game Winner Camera: How Many Batteries Are Required?

You may want to see also

The X-Pro series are made in Japan

The X-Pro series is part of Fujifilm's X-Series of cameras. The X-Pro series are made in Japan, with the “Made in Japan” label confirming that every part of the camera's construction has met Fujifilm's highest standards. The X-Pro series is a line of mirrorless interchangeable-lens digital cameras. The X-Pro1, the first in the series, was released in 2012, with the X-Pro2 released in 2016 and the X-Pro3 in 2019.

The X-Pro series has a sleek, black body, with the top cover and base plate made from corrosion-resistant titanium and the rest of the body shell made from magnesium alloy. The titanium and painted finish are designed to age beautifully, adding to the camera's appeal and highlighting its robust yet understated style. The X-Pro series also features a unique viewfinder, with the option to switch between an optical viewfinder (OVF) and an electronic viewfinder (EVF). This makes the series popular with street photographers, as the OVF provides a view outside of the framelines, allowing them to see what might be entering their shot.

The X-Pro series has received positive reviews, with praise for its high ISO performance, image quality, and durability. The series has also been commended for its colour accuracy, with the "X-Trans" CMOS sensor claimed to provide higher resolution than full-frame sensors and produce better colour reproduction. The autofocus speed has been improved with firmware updates, and the camera's “Kaizen” approach means continual updates and innovation.

Charging Night Owl Cameras: A Step-by-Step Guide

You may want to see also

The X-T3/4/5, X-H2, and X-H2S are made in China

The Fujifilm X-T3, X-T4, and X-T5 are made in China, as are the X-H2 and X-H2S. This is in contrast to most of Fujifilm's other cameras, which are made in Japan. The X-T3 is a mirrorless compact camera that was announced on September 6, 2018, and is the successor to the 2016 Fujifilm X-T2. The X-T4 was announced on February 26, 2020, as the successor to the X-T3, which continued to be offered for sale even after the X-T4's introduction. The X-T5 is a newer model that appears to have been released around 2024.

The X-H2 is another mirrorless camera produced by Fujifilm. It has a similar form factor to the X-H2S, which is the company's latest high-speed flagship model and the successor to the X-H1 from 2018. The X-H2S features a 26-megapixel X-Trans CMOS 5 HS imaging sensor, which is both stacked and backside-illuminated, allowing it to read data four times faster than Fujifilm's previous X-Trans CMOS 4 sensor. It also offers ProRes internal, ProRes RAW, and BRAW external recording. The X-H2S is priced at $2,499 and was released on July 7, 2022.

While Fujifilm proudly etches "Made in Japan" onto almost all of its mirrorless cameras, some models are now produced in China. This move may be due to cost considerations or the availability of specialized manufacturing capabilities in China. It is worth noting that even products assembled in China may have components sourced from various countries, including Japan.

The Rare 1970 Z28 Cameros: How Many Were Produced?

You may want to see also

Fujifilm's Taiwa factory in Sendai handles final assembly for its most prestigious products

Fujifilm is a Japanese multinational conglomerate headquartered in Tokyo, Japan, with operations spanning various industries, including photography, optics, biotechnology, and chemicals. While the company has expanded its production and operations globally, its connection to Japan remains strong, especially in regard to its camera manufacturing.

The Fujifilm Taiwa factory in Sendai, Japan, is a key site for the company, handling the final assembly of some of its most prestigious products. This includes cameras like the X100T, the X-T1, and the X-Pro2, as well as high-end lenses. The process involves bringing together components, some of which are produced elsewhere in Japan, such as the metal body of the X-Pro2, which is cast in another factory in the country.

The Taiwa factory is not just a symbol of Fujifilm's commitment to quality and craftsmanship but also a testament to the company's trust in its skilled workforce. The assembly of these prestigious products is done by hand, with each camera carefully put together by workers who take pride in their work. This level of care and attention to detail is a hallmark of Fujifilm's approach to manufacturing.

The Sendai factory is strategically located about 20 miles from the city centre, and it takes around 45 minutes to reach by bus. This location provides the necessary space for the complex assembly operations while also offering relatively easy access to the rest of the country and the world, facilitating the distribution of these prestigious products to customers worldwide.

Fujifilm's decision to base the final assembly of its most prestigious products at the Taiwa factory in Sendai underscores the company's dedication to quality and precision in its camera manufacturing. The combination of skilled workers, efficient processes, and a strategic location makes the Sendai factory a cornerstone of Fujifilm's global operations and a key contributor to the company's success in the highly competitive camera market.

Charging the Eufy 2C: Know When It's Ready

You may want to see also

Fujifilm has a manufacturing hub in Greenwood, South Carolina

FUJIFILM Manufacturing U.S.A., Inc. is a wholly-owned subsidiary of FUJIFILM Corporation, with its North American Manufacturing and Research and Development Headquarters established in Greenwood, South Carolina, in 1988. The Greenwood site is one of the company's global manufacturing hubs, playing a key role in the company's strategic vision and serving customers throughout the United States, Canada, and over 40 other countries worldwide.

The complex in Greenwood, South Carolina, encompasses over 500 acres and represents a significant investment of over $1.8 billion. With more than 2.5 million square feet of manufacturing space, the site boasts five state-of-the-art manufacturing facilities for the production of QuickSnap recyclable cameras, inkjet photographic paper, colour photographic paper, and digital printing plates. The Greenwood complex has also obtained prestigious ISO-9001:2015 and ISO-14001:2015 registrations, demonstrating Fujifilm's commitment to excellence in quality and environmental protection and preservation.

The Greenwood site currently employs over 1000 people, with approximately 500 associates working in the manufacturing facilities. The site includes the Greenwood Research Laboratories and Fujifilm's largest distribution centre in the world. The company's presence in Greenwood, South Carolina, is a testament to the pro-business environment and skilled workforce that the state offers.

FUJIFILM Manufacturing U.S.A., Inc. has continued to expand its operations in Greenwood County, with a recent $3.9 million investment in 2018 to assemble electrical parts for inkjet printer heads. This expansion demonstrates the company's commitment to the community and its continued growth in South Carolina. The company's address in Greenwood is 211 Puckett Ferry Road, Greenwood, SC 29649.

How to Keep Date and Time Settings on Canon A560

You may want to see also

Frequently asked questions

No, Fujifilm manufactures cameras in several countries, including Japan, China, the Philippines, Vietnam, and Indonesia.

Fujifilm's prestigious X-Pro series cameras, such as the X-Pro2 and X-Pro3, are made in Japan.

Yes, Fujifilm has a manufacturing hub in Greenwood, South Carolina, that produces QuickSnap recyclable cameras, among other products.

Fujifilm states that its cameras are manufactured to the same quality standards, regardless of the factory location. However, some consumers still express a preference for cameras made in certain countries.

Yes, some Fujifilm camera models, such as the X-T4 and the X-T5, are made in China.