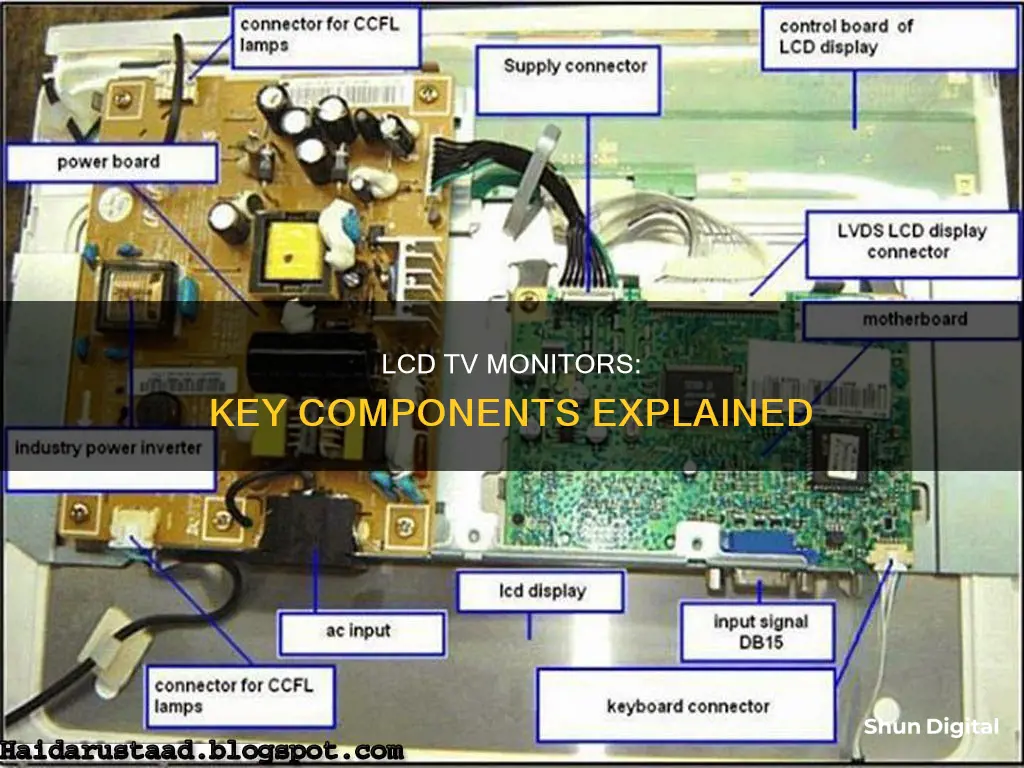

LCD TV monitors are made up of several components, each serving a unique function to ensure the optimal functioning of the screen. The main components include a power supply board, a main board, a wifi/bluetooth module, speakers, a key controller, an IR sensor, a T-Con board, an LED driver, LED strips, and the screen (panel).

The power supply board converts AC voltage from the outlet to various DC voltages to power the TV. The main board acts as the brains of the TV, controlling everything from audio to video streams and storing user data and settings. The wifi/bluetooth module enables connection to wifi and nearby bluetooth devices.

The IR sensor, or infrared sensor, receives the signal from the remote control and sends it to the main board as an electronic signal. The T-Con board, or timing control board, is found in LED and CCFL TVs and converts the video signal from the main board to display on the screen.

The LED driver, unique to LED TVs, controls the LED strips or bars behind the screen, managing their power and brightness. Finally, the LED strips serve as the light source behind the LCD screen, with their power and brightness controlled by the LED driver or power supply board.

While the specific components may vary across manufacturers and models, these are the primary elements that work together to bring your favourite shows to life on an LCD TV monitor.

| Characteristics | Values |

|---|---|

| Screen | LCD (Liquid Crystal Display) |

| Main Components | Polarized glass, liquid crystal molecules, transparent conductive materials, backlight, reflector sheet, light guide plate, diffuser sheets, prism sheet, glass substrate (backplane), power supply and common electrode |

| Backlight | LED or fluorescent lighting |

| Power Source | Power supply board |

| Brain | Main board |

| Connectivity | Wi-fi/Bluetooth module |

| Signal Receiver | IR sensor |

| Video Processing | T-Con board |

| Light Source | LED strips or CCFL backlit TVs |

| Light Control | LED driver |

What You'll Learn

Polarized glass sheets

Polarizers enable vertical light waves to pass through the filter and reach the light-bending liquid crystals. Horizontal light waves, on the other hand, are blocked or filtered out as they distort the image quality. This is because polarized glass will pass light waves at a certain angle, and if two sheets are placed one after the other with the same polarization, the light will pass through both. However, if the first sheet has a polarization that is perpendicular to the second sheet, no light will pass through.

Since polarizers are made of a plastic-like material, they are sensitive to extremely hot and humid temperature conditions.

Latest ASUS Monitors: Top Picks for 2023

You may want to see also

Liquid crystal molecules

Liquid crystals are a key component of LCD screens, contributing to picture quality, sharpness, and brightness. They are electrically charged molecules that have the ability to block or allow light to pass through. Each liquid crystal is charged with an electric current, allowing them to be manipulated to form specific patterns that result in the images we see on our screens.

Liquid crystals are unique in that they can pass light through and are affected by electrical currents, which change the way light passes through them. They are liquid but possess crystalline properties, with their molecules arranged in a regular pattern, lying parallel to the glass plates of the screen. This gives the crystals their crystal-like properties, including the ability to rotate the plane of polarisation of light as it passes through.

The molecules of nematic liquid crystals are aligned with their axes in parallel. In contrast, smectic liquid crystals arrange themselves in layered sheets, with their molecules taking on different alignments relative to the plane of the sheets. The optical properties of liquid crystals depend on the direction of light travel through the layer of material.

An electric field can change the orientation of the molecules in a layer of liquid crystal, affecting its optical properties. This is known as an electro-optical effect and forms the basis for LCDs. The small electric voltages necessary to orient liquid crystal molecules are a key feature of the commercial success of LCDs, as other display technologies rarely match their low power consumption.

The inner surfaces of the glass in an LCD are printed with a transparent film of conductive material, such as indium oxide or indium tin oxide, to form electrodes. The liquid crystal layer is sandwiched between two glass plates, with the molecules normally lying parallel to these plates. When a voltage is applied, the liquid crystal molecules are affected, with the degree of deformation and light blockage dependent on the volume of electricity passed through. This allows for the display of various shades of grey and, when combined with red, blue, and green subpixels, a full spectrum of colour.

Monitor Sizes: Common Display Dimensions for Your Setup

You may want to see also

Transparent conductive materials

The use of transparent conductive materials is crucial to the functioning of LCD screens. By allowing electric current to reach each pixel, these materials enable the manipulation of liquid crystal molecules, which are affected by electrical currents and play a key role in how light passes through the screen to form images.

In addition to their conductivity and transparency, these materials must also possess certain optical and mechanical properties to be suitable for use in LCD screens. They should have high light transmission, low absorption in the visible spectrum, and minimal haze to ensure optimal image quality. Furthermore, these materials should be durable and resistant to scratches and other types of damage to withstand the manufacturing process and everyday use.

Indium tin oxide (ITO) is a commonly used transparent conductive material in LCD screens due to its favourable electrical, optical, and mechanical properties. ITO offers high conductivity, excellent light transmission, and good scratch resistance. However, it is important to note that ITO also has some limitations, such as limited flexibility and high electrical resistance compared to newer alternatives like graphene and carbon nanotubes.

In recent years, there has been a growing trend towards exploring alternative transparent conductive materials to ITO due to its limitations and the increasing demand for flexible and lightweight electronic devices. These alternative materials include graphene, carbon nanotubes, conductive polymers, and metal nanowires, each offering unique advantages in terms of conductivity, flexibility, and optical properties.

The development and optimisation of transparent conductive materials continue to be an active area of research and innovation, with the goal of creating more efficient, flexible, and cost-effective solutions for LCD screens and other electronic devices.

Dealing with Multiple Monitors: A Size Guide

You may want to see also

Backlight

The backlight is a crucial component of an LCD TV monitor, providing illumination from behind the display panel. As LCDs do not emit light on their own, the backlight is necessary to produce a visible image. The backlight is usually the first layer from the back of the monitor, with light valves controlling the amount of light that reaches the viewer's eye.

The backlight is typically one of two types: Light-Emitting Diodes (LEDs) or Cold Cathode Fluorescent Lamps (CCFLs). LEDs are the more modern and increasingly popular option, offering lower power consumption and better contrast. CCFLs, on the other hand, were commonly used in older LCD monitors and require higher voltages to operate.

The backlight in an LCD TV monitor can be thought of as a lighting source that shines through the LCD crystals, which either block or allow light to pass through. This light then passes through various layers, including polarizing filters and liquid crystal molecules, to create the images we see on the screen.

In recent years, LED backlighting has become more common, offering advantages such as thinner panel designs, high-speed switching, and longer lifespans compared to CCFLs. LED backlights are also often dynamically controlled using video information, allowing for local dimming and an improved high dynamic range.

While LED backlights are now dominant, it's worth noting that other light sources have been used historically, such as incandescent light bulbs and hot cathode fluorescent lamps (HCFLs). However, these options had limitations due to their heat generation and shorter lifespans.

In summary, the backlight is a critical component of an LCD TV monitor, providing the illumination necessary for the display to function. The advancements in backlight technology, particularly the shift from CCFLs to LEDs, have played a significant role in improving the performance and energy efficiency of LCD screens.

Best Monitor Alternatives to the ASUS PG279Q

You may want to see also

Inverter

An inverter is a crucial component of an LCD TV monitor, responsible for providing the required current and voltage to the backlight module. The backlight, typically consisting of fluorescent bulbs or LEDs, illuminates the LCD screen and enables the display of images. Without the inverter, the screen would appear shut off, even though the display is still rendering images.

The inverter plays a vital role in ensuring the brightness and visibility of the LCD screen. It converts the DC power from the power outlet, which is suitable for digital components like the motherboard, into AC power required by the fluorescent bulbs. This process involves intercepting the DC power and transforming it back into AC power, ensuring the bulbs receive the necessary voltage to function.

The inverter is a delicate component, and working with it requires caution due to the extremely high voltage it carries. Troubleshooting and repairing an inverter often involve checking for burnt traces, cracked components, or bulging capacitors. It is important to approach repairs carefully and ensure that safety precautions are followed to avoid electrical shocks.

Monitoring PCI Bus Usage: Linux Command Line Essentials

You may want to see also