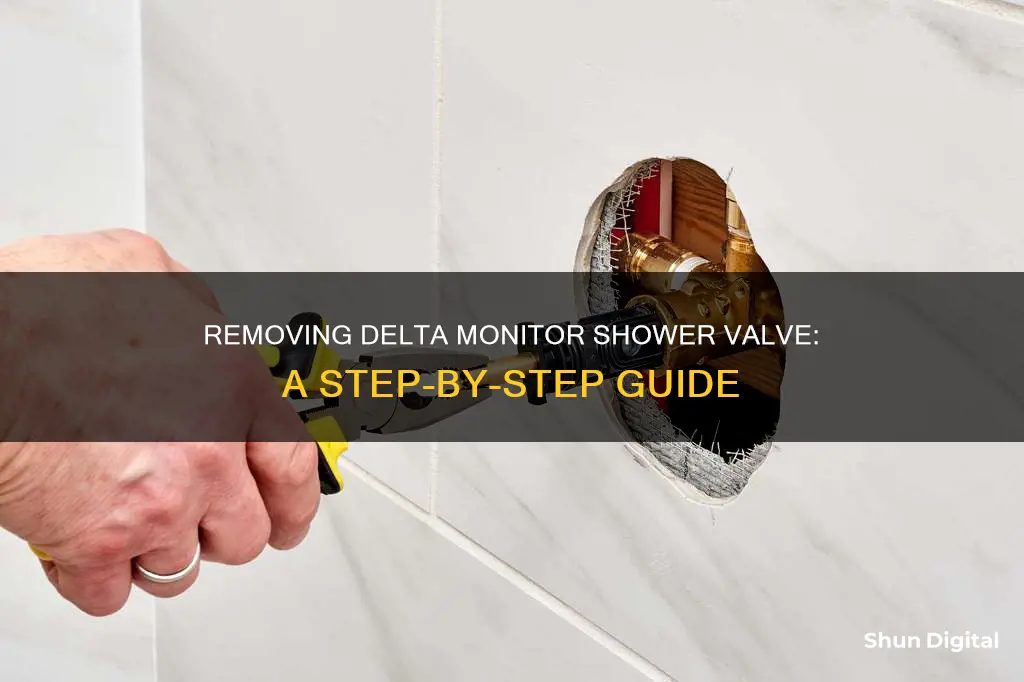

Removing a Delta Monitor shower valve can be challenging and time-consuming, but it is a satisfying DIY task. The process involves several steps, including preparing the necessary tools, shutting off the water supply, and carefully disassembling the faucet. It is important to note that specific models, such as the Delta 1500 series, may have unique requirements, such as the need for a conversion kit to upgrade to a newer series. In all cases, it is essential to identify the correct tools and replacement parts to avoid complications during the removal and reassembly process.

What You'll Learn

Shut off the water supply

To remove a Delta Monitor shower valve, you must first shut off the water supply. This is an essential step to prevent any water wastage and make the repair process safer and more efficient. Here is a detailed guide on how to shut off the water supply:

Locate the Main Water Shut-Off Valve: Before beginning any repair work on your Delta Monitor shower faucet, you must locate and shut off the main water supply valve. This valve controls the flow of water to your entire home, so turning it off will ensure that no water enters the shower faucet during the repair process.

Turn Off the Main Valve: Once you have located the main water shut-off valve, turn it clockwise to the off position. In most cases, you will need to use a wrench or your hand to turn the valve. Make sure that the valve is tightly closed to prevent any water flow.

Check the Shower Faucet: After shutting off the main valve, go to the bathroom and turn on the shower faucet to release any remaining water in the pipes. Leave the faucet open until no more water drips from the showerhead. This step ensures that the pipes are completely drained, making it safe to work on the shower valve.

Test Other Water Sources: To confirm that the water supply is completely shut off, test other water sources in your home, such as kitchen and bathroom faucets, as well as toilet flushes. If the water is off, none of these sources should produce any water flow.

Prepare for the Repair: With the water supply shut off, you can now prepare for the repair or replacement of your Delta Monitor shower valve. Gather all the necessary tools and replacement parts, such as a faucet replacement kit, plumber's grease or putty, and a new cartridge if needed.

Remember, working on plumbing fixtures can be challenging, so it is important to take your time and follow the correct procedures to avoid any damage or leaks. Always refer to reliable sources and seek professional help if you are unsure about any steps in the process.

Monitoring Bandwidth Usage: Belkin Router Guide

You may want to see also

Remove the set screw lever handle

Removing the set screw lever handle is the first step in repairing a Delta Monitor shower faucet. It is important to be prepared for a challenging process that can take over an hour to complete. Before beginning any repair work, ensure that you have shut off the water supply to the faucet at the main source.

To remove the set screw lever handle, you will need the correct Allen wrench. First, remove the small cap at the base of the handle of the Delta Monitor shower faucet. Then, take off the temperature control handle. With these two pieces removed, you can carefully pull out the screw. If you encounter resistance, use channel-lock pliers to gently wiggle and pull the screw free.

It is important to note that there may be some variation in the design of the Delta Monitor shower faucet handles. Some models may have a Phillips head screw instead of an Allen screw. In this case, the process for removing the handle may be slightly different. The Phillips head screw may be holding the handle in place, or it may need to be removed to access a white plastic piece that covers the handle assembly.

Once the screw has been removed, you may need to gently pull off the handle. In some cases, there may be an outer knurled cap that needs to be unscrewed before the handle can be removed. Be careful not to use excessive force, as this could damage the faucet or handle.

Choosing the Right Monitor: Size Considerations

You may want to see also

Remove the cartridge

Now that the water supply is shut off and you've removed the set screw lever handle, you can remove the cartridge.

First, pull off the small cap at the base of the handle of the Delta Monitor shower faucet, then remove the temperature control handle.

Next, you'll need to remove the cartridge. Grip the cartridge at the top and drag it backwards to remove it from the Delta Monitor shower faucet head. Use channel-lock pliers to get a secure grip, especially if the cartridge is stuck in the faucet.

Before removing the cartridge, note the position of the stop on the cap. Make sure to put the valve cartridge assembly back in the same position. Normally, the stop faces left.

If the cartridge is stuck, do not pry it out with a screwdriver. Instead, use the appropriate tool. Grip the apex of the cartridge with the channel-lock pliers and then make a quarter turn counterclockwise, and then lift the cartridge out.

If your water supply has high levels of lime, rust, minerals, or other contaminants, it's a good idea to conduct regular inspections of your Delta Monitor shower faucet. Pull out the cartridge as described above. Turn the cartridge valve to the full mix position and shake it vigorously. If there is a rattling noise, you can reinstall it. If there is no noise, replace it.

Troubleshooting TCP Port Monitor Absence

You may want to see also

Reassemble the faucet

Now that you have fixed the Delta Monitor shower valve, it is time to reassemble the faucet. This process will be the reverse of the disassembly process.

First, replace the O-ring. This is important to prevent leaks, and it is a good idea to replace it as a precautionary measure. Next, put the bonnet plate back in place, securing it with the two screws adjusted with a star screwdriver. Then, carefully twist and push the chrome housing back into place.

Now, replace the temperature-adjusting knob and the handle. Secure the handle with the two screws on either side, using the Allen key. Put the small cap back in place, and then replace the trim on the handle.

Finally, turn the water supply back on and check for leaks. Open the shower taps and slowly turn on the water supply. Check the pressure and the temperature, and make sure there are no leaks. If there are no issues, your Delta Monitor shower valve is now fully reassembled and ready to use!

Is Your Monitor Flicker-Free? Here's How to Tell

You may want to see also

Conduct regular inspections

Conducting regular inspections of your Delta Monitor shower valve is important to ensure it is functioning properly and to prevent any potential issues. Here are some guidelines to help you with the inspection process:

Frequency of Inspections:

- It is recommended to inspect your Delta Monitor shower valve at least once every three months. However, if you notice any issues such as leaks, reduced water pressure, or unusual noises, inspect the valve as soon as possible.

- If your water supply has high levels of lime, rust, minerals, or other contaminants, more frequent inspections may be necessary.

Steps for Inspection:

- Turn off the Water Supply: Before beginning your inspection, make sure to shut off the water supply to the shower valve. This will prevent any accidental water discharge during the inspection.

- Remove the Handle and Trim: To access the internal components of the shower valve, carefully remove the handle and trim. Keep track of the order in which you remove the parts to facilitate reassembly.

- Inspect the Cartridge: With the handle and trim removed, you can now inspect the cartridge. Look for any signs of damage, wear, or debris accumulation. Pay close attention to the O-rings and other sealing elements.

- Test the Cartridge: As per the instructions provided by Delta, pull out the cartridge and turn the cartridge valve to the full mix position. Shake it vigorously. If you hear a rattling noise, it indicates that the cartridge is functioning correctly and can be reinstalled. If there is no noise, it is recommended to replace the cartridge.

- Reassemble and Test: After completing your inspection and making any necessary repairs or replacements, carefully reassemble the shower valve in the reverse order of disassembly. Once reassembled, turn on the water supply and test the shower valve to ensure proper functioning.

By conducting regular inspections and following the above guidelines, you can help maintain the proper functioning of your Delta Monitor shower valve and identify any potential issues early on. Remember to always refer to the official Delta instructions and guidelines for specific details pertaining to your particular model.

Signs Your Monitor is Failing and Needs Replacing

You may want to see also

Frequently asked questions

First, remove the hot/cold cap and the Philips head screw. Then, pull off the white plastic piece behind it. Next, remove the 11/16th nut holding the handle assembly.

After removing the handle, you will see a sleeve and a larger ring nut holding the cartridge in place. Remove the sleeve and then the ring nut.

Use channel-lock pliers to grip the top of the cartridge securely and drag it backward to remove it from the faucet head.

Before removing the valve cartridge assembly, note the position of the stop on the cap. Ensure that you put the valve cartridge assembly back in the same position, usually facing left.