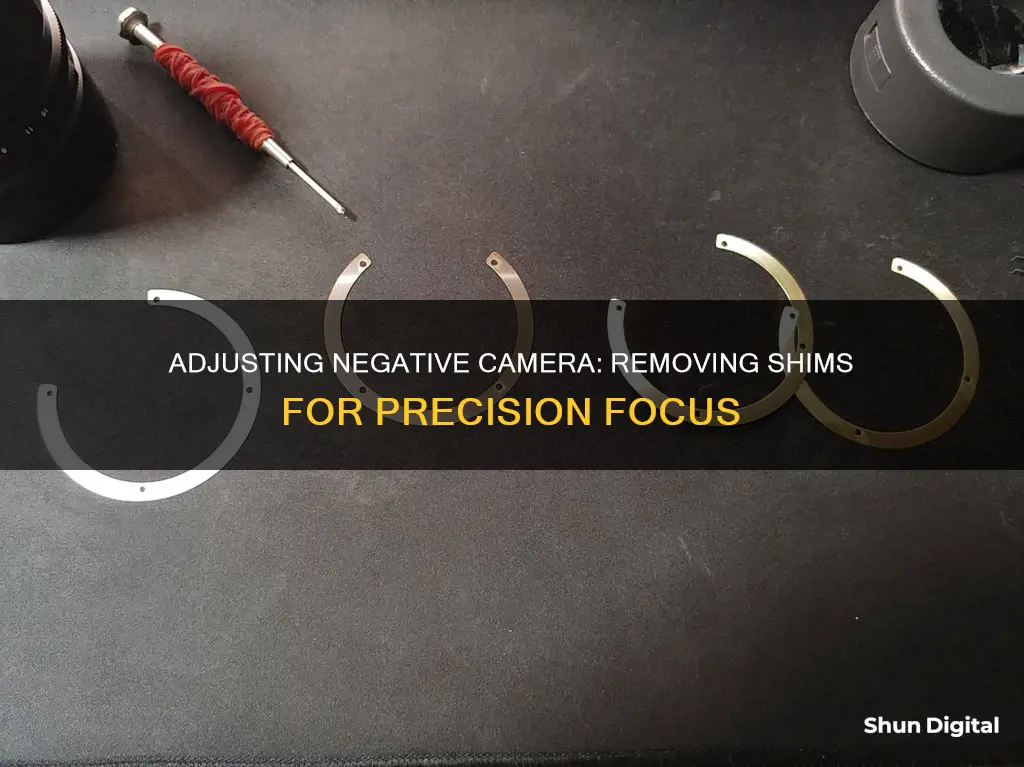

Shims are used to adjust the angle of a camera, particularly in the case of rearview cameras, where the angle is nearly straight down and not very useful. Shims can be used to tilt the camera upwards, allowing the driver to see what they are about to back into, rather than what they are about to back over. Shims are also used to adjust back focus and infinity focus issues in cameras and lenses. Shims are placed between the lens and the lens mount on the camera, and they can be removed or added to adjust the focus. Removing shims usually helps clear up infinity focus issues. However, removing too many shims can result in focus issues, gear binding, and even prevent the lens from being mounted or removed from the camera.

What You'll Learn

- Shims can be used to adjust the rear camera angle, allowing you to see what you're about to back into, rather than just down

- Shims can be used to correct back focus issues

- Shims can be used to correct infinity focus issues

- Shims can be used to adjust the lens mount to the correct flange distance

- Shims can be used to adjust the working distance of telecentric lenses

Shims can be used to adjust the rear camera angle, allowing you to see what you're about to back into, rather than just down

Shims can be used to adjust the angle of a backup camera, allowing you to see what you're about to back into, rather than just looking down at the hitch. This is especially useful if you want to see what's behind your vehicle, instead of what's directly under it.

Adjusting the angle of a backup camera can be done in several ways, depending on the type of camera and how it is mounted. Some cameras are easy to adjust within their casing, while others require tools to remove, adjust, and refasten. If your camera enclosure has screws and bolts, you'll need a drill or screwdriver to open it.

One way to adjust the angle of your backup camera is by using shims. Shims are thin pieces of material, usually metal, that can be placed between the camera and its mount to change the angle of the lens. This method is simple and effective, and it doesn't require any special tools or equipment. Simply remove the camera bracket screws, place the shims between the bracket and the body of the vehicle, and then put the screws back in and tighten them. This will tilt the camera upwards, giving you a better view of what's behind your vehicle.

When using shims to adjust the angle of your backup camera, it's important to note that the stock mounting screws may no longer sit flush on the bracket. However, this won't affect the security of the camera. You can also use longer screws if you want to sandwich the bracket between two shims, which will square up the hardware again. Additionally, you can design and 3D print your own shims, or purchase them online.

It's recommended to have a second person help with the adjustments. One person can move the camera while the other watches the monitors and directs the adjustment. This will ensure that the camera is positioned correctly and securely.

Device Manager Woes: Camera Unavailable

You may want to see also

Shims can be used to correct back focus issues

Shims are thin stainless steel spacers that can be used to correct back focus issues. They are placed between the lens and the camera to control the working distance (WD) with fine precision and guarantee the best image quality. This is especially useful for telecentric lenses, which have a fixed magnification and require precise control of the WD to achieve the best possible image.

When a lens is switched between different cameras, even if they are the same model, there may be small variations in the components that can affect the image distance and, consequently, the image quality. Shims can be used to make minor adjustments to the image distance, bringing the focus and modulation transfer function (MTF) back to optimum levels. This is also useful when there are tolerancing issues in the housing design or sensor placement, as shims can be used to correct for deviations from the nominal design.

The relationship between image distance, WD, and focal length is important when adjusting the back focus. As the image distance increases, the WD must decrease, and vice versa. This relationship can be manipulated by adding or removing shims at the rear of the lens, allowing users to adjust the WD into a usable range.

It is important to note that shims should be used judiciously, as they can impact image quality. The best performance is typically achieved when the lens is used within its design range, without the need for shims. Additionally, shims should not be used if they are more than half of the focal length, as this can further degrade image quality.

The Mystery of Smart TV Camera Holes: Location and Purpose

You may want to see also

Shims can be used to correct infinity focus issues

To correct infinity focus issues, the correct amount of shimming material needs to be added. This can be done by unscrewing the mount of the adapter and adding shims until infinity focus is spot on. The shims can be made from folded tinfoil, self-adhesive copper foil, or metal shims. It is important to start with a little less shimming material than needed and test, then add more as needed. Once the correct amount of shimming material has been added, the screws can be put back in and the setup can be tested.

It is important to note that this method may not result in a super exact alignment of the adapter. It is also crucial to ensure that the shims are thin enough so that the mount bolts can still be secured safely. Additionally, it is recommended to vacuum the adapter after adding shims to remove any loose particles that could contaminate the sensor.

Another way to correct infinity focus issues is to adjust the lens itself. This can be done by loosening the screws that constrain the focusing range and turning the helicoids so that they focus perfectly at infinity. The focusing ring can then be adjusted to align with the infinity symbol. This method is more precise and is recommended for lenses that can be adjusted.

Surveillance Cameras: Watching Our Every Move

You may want to see also

Shims can be used to adjust the lens mount to the correct flange distance

Shims are thin stainless steel spacers that can be used to adjust the lens mount to the correct flange distance. The flange focal distance, or flange depth, refers to the distance between the camera's mounting flange and the film or sensor plane. This distance varies between cameras and lens mounts, which is why lens mount adapters are designed to be slightly thinner than the calculated difference in flange distance to allow lenses to focus past infinity.

Shims can be used to fine-tune this distance, ensuring that the lens is correctly positioned relative to the sensor. This is particularly important for telecentric lenses, which have a fixed magnification and require precise control of the working distance (WD). By adding or removing shims at the rear of a telecentric lens, one can adjust the WD to match the specific requirements of an application.

The use of shims can also compensate for tolerances in housing design or sensor placement, ensuring that the lens is correctly positioned for optimal image quality. Shims are often included with telecentric lenses to allow for fine-tuning during setup.

It is important to note that image quality can be affected by deviations from the ideal image distance. If the image distance is too far from the ideal design, blur or degradation in the modulation transfer function (MTF) may occur. Shims provide a way to adjust the image distance and bring the MTF and focus back to optimal levels.

In summary, shims are a valuable tool for adjusting the lens mount to the correct flange distance, particularly for telecentric lenses and applications requiring precise control of the working distance.

The Evolution of Television Cameras: What Are They Called?

You may want to see also

Shims can be used to adjust the working distance of telecentric lenses

The flange distance can vary slightly from the nominal design due to tolerancing in the housing design or sensor placement. Shims may be used as thin spacers between the lens and camera to correct for this deviation. As image distance varies, so can image quality. If the image distance is shifted too far from the ideal design, a noticeable blur or degradation in MTF (modulation transfer function) can occur.

Minor adjustments can be made using shims to bring the MTF and focus back to optimum levels. Shims are often included with many telecentric lenses. With critical optical parameters set for each system, software thresholds and calibration procedures will be repeatable from one system to the next.

Telecentric lenses are often chosen for applications requiring demanding manufacturing measurements. These applications may include other challenges, such as limited working distance ranges due to swinging robotic arms, nearby contaminations, or the existing mechanical layout of a machine. Adding or removing shims at the rear of a telecentric lens takes advantage of the relationship between image distance, working distance, and focal length. This adjusts the working distance slightly into a usable range.

In monochromatic applications, shims can also be used to compensate or refocus for chromatic focal shift. Shims give users precise control of image distance to achieve the best possible solution for their application.

The Crucial Role of TV Camera Operators

You may want to see also

Frequently asked questions

Shims are used to adjust the back focus of a lens to account for manufacturing tolerances and precisely adjust it to the registration distance of the camera mount. They ensure that when the optical lens elements are positioned for infinity focus, the image is precisely in focus on the sensor.

Shims can cause a small degradation of sharpness and micro-contrast, but they do not affect macro-contrast or depth of field.

Too many shims can prevent a lens from focusing on infinity. Too few shims can result in focus past infinity, which is a problem for autofocus. Removing shims may also cause the AF gear to bind, leading to stiff manual focus and very slow AF movements.

If your camera cannot focus on infinity or achieve reasonable autofocus adjustment, it may need shims.

You can add or remove shims from between the lens and the camera mount to change the focus distance. Shims are typically very thin (0.025 - 1.0mm) and made of stainless steel or aluminum foil.