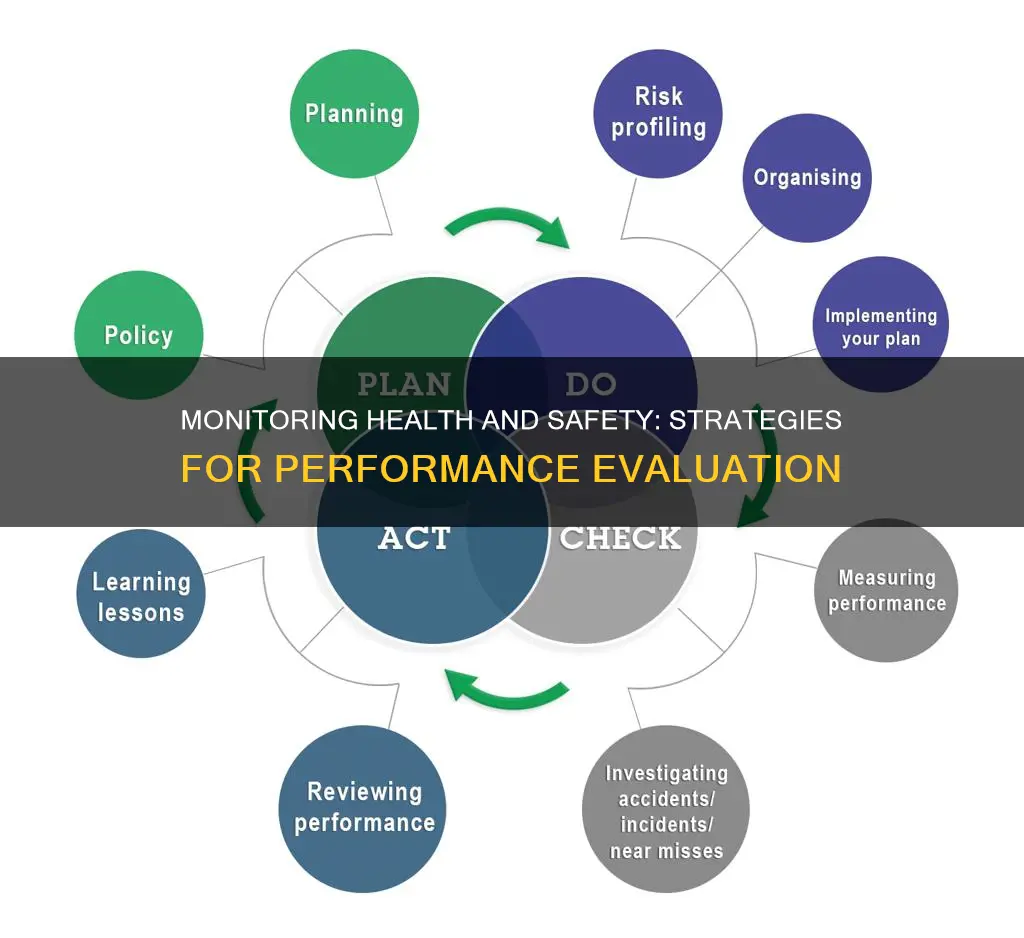

Monitoring health and safety performance is crucial for organisations to ensure the well-being of their employees and the success of their business. While the ultimate goal is zero accidents, illnesses, and harm, it is essential to go beyond tracking incident statistics and adopt a comprehensive approach to performance measurement. This includes analysing safety processes, identifying risks, evaluating policies, and conducting accident investigations. By implementing various measurement systems and strategies, organisations can navigate potential issues, make data-driven decisions, and foster a positive health and safety culture. Additionally, monitoring can help meet legal requirements, maintain compliance, and enhance the overall work environment, resulting in increased efficiency and productivity.

What You'll Learn

Near-miss reporting

The process of near-miss reporting typically involves the following steps:

- Ensure Safety: After a near miss occurs, the first priority is to ensure the safety of everyone involved. This includes removing individuals from unsafe areas, checking for any injuries, and clearing any hazardous materials or obstacles.

- Identify Location and Equipment: It is important to identify the specific location and any equipment involved in the near miss. This information helps management understand the context and take targeted measures to prevent future incidents.

- Gather Employee Perspectives: Communicate with employees involved in or witnessing the near miss to gather their perspectives. This can provide valuable insights into the circumstances and potential causes of the incident.

- Notify Supervisor: Inform your direct supervisor or a member of management about the near miss. They may initiate an investigation to determine the underlying causes and develop strategies to prevent similar incidents.

- Submit an Official Report: You may be asked to submit a detailed report of the near miss, including the date, time, location, individuals involved, and any relevant witnesses. This documentation is crucial for data collection and safety analysis.

- Discuss Risk Minimization Strategies: Near-miss incidents provide valuable information about potential hazards. Collaborate with management and provide input on how to reduce the risk of similar incidents in the future.

The benefits of near-miss reporting are significant. It helps identify risks, improves internal data collection, and enhances employee support. By reporting near misses, management can address equipment issues, improve safety protocols, and make data-driven decisions to create a safer work environment. Additionally, near-miss reporting encourages a culture of safety and empowers employees to speak up without fear of blame or punishment.

To further enhance the effectiveness of near-miss reporting, organisations should strive to create a culture of safety and encourage open communication. This includes providing clear guidelines on reporting procedures, assuring employees of confidentiality, and promoting a blame-free environment. Regular safety meetings, training sessions, and awareness campaigns can also contribute to a safer workplace.

Cleaning an LCD Monitor: Streak-Free Tips and Tricks

You may want to see also

Health and safety inspections

A health and safety inspection can check for a variety of factors, including:

- Whether procedures for safe working are being followed, such as the correct use of PPE, a tidy work area, and suitable risk control.

- The condition of equipment and whether maintenance is up to date.

- The effectiveness of management structures and risk controls.

- The impact of changes, such as new procedures, work processes, or products.

- Compliance with legal requirements and other external developments.

Measuring health and safety performance through inspections often involves assigning a score or grade to each inspection report. For example, a site that fails 10 out of 100 items covered during an inspection would score 90%. If the same site scores 95% during the next inspection, this indicates an improvement. Repeated issues across multiple inspections may highlight an ongoing problem that needs to be addressed.

In addition to inspections, organisations can utilise near-miss reporting as a tool to identify and address health and safety issues before they result in accidents. By measuring and monitoring data from near-miss reports, organisations can pinpoint areas where problems exist and take proactive measures to prevent future incidents.

The Standard 24-Inch Monitor: How Big Is It Really?

You may want to see also

Monitoring sickness absence

Data Collection and Analysis:

- Collect and analyse sickness absence data: Track the frequency and duration of absences, including short-term and long-term sickness. Calculate the crude absence rate, which is the percentage of contracted working time lost due to sickness.

- Identify patterns: Look for trends and patterns in absence data, such as specific days of the week, seasons, or departments with higher absence rates. This can help identify underlying issues.

- Compare with industry benchmarks: Compare your organisation's absence rates with those of similar organisations in your sector to identify areas for improvement.

Procedures and Policies:

- Establish clear procedures: Implement structured procedures for measuring and monitoring absence. This includes tracking working days lost, absence patterns, individual worker absence frequency, and reasons for absence.

- Authorised and unauthorised absence: Differentiate between authorised and unauthorised absence, whether sickness-related or not. This helps identify issues related to workplace conditions or employee misconduct.

- Return-to-work interviews: Conduct sensitive return-to-work interviews to uncover hidden reasons for absence, assess fitness to work, identify underlying medical conditions, and determine the likelihood of recurrence.

Management Strategies:

- High-level management commitment: Ensure that senior management is actively involved in monitoring and reducing sickness absence. This includes allocating resources and supporting initiatives to improve employee health and wellbeing.

- Clear responsibilities: Define clear roles and responsibilities for monitoring and managing absence, with line managers being suitably trained to recognise and address absence issues.

- Attention to staff welfare: Prioritise staff welfare by offering flexible working patterns, stress management training, and support for employees dealing with work-related or personal issues.

- Involve workers: Engage employees in the monitoring process to increase buy-in and encourage a culture of mutual support for health and safety.

Performance Measurement:

- Set targets and goals: Establish baseline data on current absence levels and set measurable targets for improvement. Define key performance indicators (KPIs) and track progress over time.

- Measure health and safety inspections: Conduct regular health and safety inspections to identify breaches or problems. Score each inspection to quantitatively track improvements or ongoing issues.

- Near-miss reporting: Encourage employees to report near misses to identify potential health and safety issues before accidents occur. Measure and monitor this data to take proactive corrective actions.

By implementing these strategies, organisations can effectively monitor and manage sickness absence, improving overall health and safety performance in the workplace.

Is Your Monitor G-Sync? How to Find Out

You may want to see also

Benchmarking against competitors

Benchmarking is a critical aspect of monitoring health and safety performance, allowing organisations to evaluate their standing relative to competitors within the same industry sector. This comparative analysis provides valuable insights for strategic decision-making and performance enhancement. Here are some essential considerations for effective benchmarking:

Data Collection and Key Performance Indicators (KPIs)

To benchmark health and safety performance accurately, organisations should collect relevant data and establish specific KPIs. These KPIs serve as measurable indicators, facilitating comparisons with industry peers. Examples of KPIs include accident and incident rates, sickness absence percentages, and performance metrics related to safety equipment usage and maintenance. By defining clear KPIs, organisations can systematically track and assess their health and safety performance over time.

Industry Standards and Competitor Analysis

Benchmarking entails comparing an organisation's health and safety performance against industry standards and competitors' practices. This involves researching and analysing the safety strategies, procedures, and outcomes of other leading companies in the same sector. By understanding the safety benchmarks within the industry, organisations can identify areas for improvement and set realistic targets. This competitive analysis enables businesses to learn from each other and strive for continuous improvement.

Periodic Reviews and Continuous Improvement

Effective benchmarking is an ongoing process that requires periodic reviews. Organisations should regularly assess their health and safety performance against that of their competitors to identify gaps and areas of excellence. By conducting frequent reviews, businesses can adapt their strategies, adopt best practices, and stay aligned with evolving industry standards. This iterative approach fosters a culture of continuous improvement, where safety performance is constantly enhanced.

Customisation and Contextualisation

When benchmarking, it is crucial to consider the unique context and characteristics of an organisation. A one-size-fits-all approach may not be effective, as each business operates within a distinct set of circumstances. Therefore, while learning from competitors is essential, organisations should tailor their health and safety strategies to their specific needs, workforce, and operational realities. Customisation ensures that benchmarking leads to practical and applicable improvements.

Collaboration and Best Practice Sharing

Benchmarking can be a collaborative process, where organisations share insights and best practices to elevate industry-wide health and safety standards. By fostering a culture of cooperation, businesses can collectively raise the bar for safety performance. This collaborative approach can be particularly beneficial when addressing shared challenges or implementing innovative solutions that require industry-wide cooperation.

In conclusion, benchmarking against competitors is a powerful tool for monitoring and enhancing health and safety performance. By collecting relevant data, establishing KPIs, conducting periodic reviews, customising strategies, and embracing collaboration, organisations can effectively benchmark their health and safety practices. This process enables businesses to identify areas of improvement, set realistic targets, and strive for continuous advancement in safeguarding the well-being of their workforce.

Connecting Ancient Monitors to 1080 FTW: A Comprehensive Guide

You may want to see also

Lead metrics

Understanding Lead Metrics

Key Areas to Monitor

When designing lead metrics, it is essential to consider a range of factors that can impact health and safety performance. This includes monitoring workforce experience and qualifications to ensure employees are competent and aware of safety procedures. Additionally, machine maintenance schedules, safety equipment features, technical specification standards, and compliance reporting requirements should be regularly assessed to identify potential hazards and ensure the effectiveness of safety equipment.

Benchmarking and Tracking Progress

Benchmarking is a crucial aspect of lead metrics. By setting benchmarks and tracking progress, organisations can identify areas of improvement and evaluate the effectiveness of their safety measures. This involves establishing baseline data, setting targets, and regularly measuring performance against these targets. It is also essential to consider industry standards and compare performance with other organisations in the same sector to identify areas requiring improvement.

Employee Engagement and Feedback

Involving employees in the monitoring process can significantly enhance health and safety performance. Organisations should encourage a two-way feedback system where employees can report unsafe conditions and suggest improvements. This not only helps identify potential hazards but also increases employee engagement in safety initiatives and fosters a culture of safety within the organisation.

Regular Inspections and Checklists

Implementing regular health and safety inspections using checklists can help identify issues before they become incidents. These inspections should be conducted according to an agreed-upon schedule, with a mix of planned and random inspections to ensure all areas of the workplace are covered. Inspections can include checking safety measures, employee behaviours, and the effectiveness of training programs. Scoring or grading inspection reports can help identify areas requiring improvement and track progress over time.

Continuous Improvement

Blind Spot Monitor: A Worthless Safety Feature?

You may want to see also

Frequently asked questions

Monitoring health and safety performance can help to identify areas of improvement and ensure that hazards and risks are being controlled within an organisation. It can also help to prevent accidents and incidents, improve the working environment for employees, and increase efficiency and productivity.

There is no one-size-fits-all approach to measuring health and safety performance. While accident statistics are a common metric, they only provide a partial snapshot of health and safety in the workplace. Organisations should also consider near-miss reporting, health and safety inspections, and health surveillance as part of their measurement strategy.

Two primary types of metrics are lag metrics and lead metrics. Lag metrics evaluate events, indicators, or outcomes that have already occurred, with the aim of preventing future accidents. Lead metrics investigate the effectiveness of key work processes and proactive measures to predict incidents. Other key metrics include incidents and near-misses, safety suggestions and hazards, and activity measures.

The frequency of monitoring may depend on the nature and complexity of the organisation's operations, the level of risk involved, and regulatory requirements. Some organisations may monitor health and safety performance daily or weekly, while others may conduct quarterly or annual assessments.