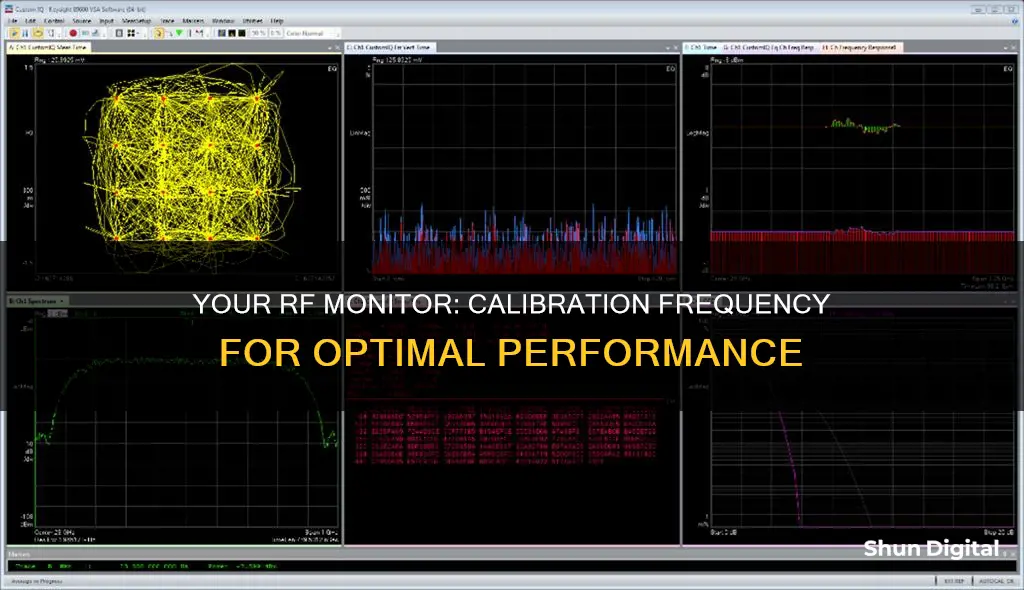

Calibration is important to ensure that the readings obtained from an instrument are consistent with other measurements and a standard typically published by a government agency. There is no one-size-fits-all answer to how often you should calibrate your RF monitor. The calibration interval depends on the application, QA requirements, industry standards, performance, safety regulations, and the environment in which the equipment is used.

For instance, if your work requires just gross voltage checks, calibrating your RF monitor seems unnecessary. However, if your equipment is exposed to an event, such as a knock or a leak, it is best to send it for calibration to ensure that the unit and its critical internal components are in good working order.

In general, you should calibrate your sensors on a fixed schedule and then monitor their performance. If you notice that they consistently provide accurate readings, you can reduce the calibration frequency. Conversely, if you use your equipment for critical measurements, you may want to calibrate it more frequently to minimise the chance of questionable test results.

Some manufacturers recommend calibrating your monitor every two to six weeks, while others suggest a range from once or twice a month for hobbyists to weekly or even daily for professionals. Ultimately, the calibration interval for your RF monitor depends on several factors, and you may need to adjust it over time as you observe the performance of your equipment.

| Characteristics | Values |

|---|---|

| How often should you calibrate your monitor? | It depends on the monitor's behaviour over time and the type of work you do. Recalibration is suggested every 2-6 weeks to ensure accuracy. |

| How long does it take? | Approximately 2 minutes per monitor when using the Datacolor SpyderX Pro. |

What You'll Learn

How often should I calibrate my RF monitor?

There is no one-size-fits-all answer to this question. The calibration interval for your RF monitor will depend on several factors, including the type of monitor, its age, usage, storage, and the nature of your work.

Manufacturer Recommendations

Datacolor recommends calibrating your monitor monthly, while X-Rite suggests a range from once or twice a month for hobbyists to weekly or even daily for professionals. These are safe recommendations to follow, but you should also consider the unique characteristics of your monitor and your specific needs.

Monitor Behaviour Over Time

Modern LCD monitors with IPS panels are generally stable and exhibit minimal colour drift over time. However, older monitors with CCFL fluorescent lamp backlights tend to drift more. Additionally, higher-end displays are manufactured with stricter tolerances and often have better hardware mechanisms to compensate for drift. Therefore, the calibration interval can be longer for newer, high-quality monitors and shorter for older ones.

Nature of Your Work

The required calibration frequency also depends on the level of colour accuracy needed for your work. For example, a web developer can tolerate a less colour-accurate monitor than a product photographer who needs to deliver colour-correct files. If your work heavily relies on colour accuracy, consider calibrating your monitor at least once a week.

Environmental Factors

If your monitor is routinely transported, exposed to varying temperatures, or subjected to physical impacts, it may require more frequent calibration. Establishing an annual or semi-annual calibration schedule and adjusting it based on observed results is a good practice.

In summary, the ideal calibration interval for your RF monitor will depend on various factors, including the monitor's characteristics, your usage patterns, and the precision required for your work. A good starting point is to calibrate monthly and then adjust the interval based on the stability of your monitor's performance and colour accuracy.

Best ASUS Monitors for 2K 144Hz Gaming Experience

You may want to see also

How long does it take to calibrate an RF monitor?

The time it takes to calibrate an RF monitor depends on the calibration tool being used. Using a basic test pattern, the process can be done with "reasonable accuracy", though it may take a few tries to get the desired results. This method is not suitable for critical work in a professional setting.

Using a calibration tool, such as a tristimulus colorimeter, can provide a more accurate calibration. This method requires an investment in equipment and software, or the contracting of a professional calibrator, which can be costly. The automatic calibration process involves the colorimeter testing the monitor's colours against industry colour standards, mapping the variations, and creating a unique colour profile. This process can take around 15 minutes, with only a few minutes of user interaction required.

Some sources suggest that calibrating an RF monitor can be done in as little as two minutes using tools such as the Datacolor SpyderX Pro. However, the time required may vary depending on the specific monitor and calibration tool being used.

Spotting Irregularities: Process Monitoring Tips and Tricks

You may want to see also

What are the benefits of calibrating an RF monitor?

Calibration is an important process for any device that gives readings or measurements, and RF monitors are no exception. Calibration ensures that the readings obtained from an instrument are consistent with other measurements and standards published by government agencies or industry standards. This is especially critical in crowded RF environments, where technicians need to have a high level of confidence in their test equipment.

Consistency with Measurements and Standards

Calibration ensures that the readings obtained from an RF monitor are consistent with other measurements and standards published by government agencies or industry standards. This is especially critical in crowded RF environments, where technicians need to have a high level of confidence in their test equipment.

Accuracy

Calibration determines the accuracy of the readings displayed on the RF monitor. Over time, the readings may drift, and calibration helps to correct this, ensuring that the monitor can be trusted and is consistently reliable.

Safety

In some cases, calibration is the key to negating a recall, out-of-tolerance condition, or potential safety concern. This is particularly important in industries with strict regulations, such as pharmaceuticals, where calibrating before and after a critical measuring project may be required.

Cost-Effectiveness

Depending on the usage and requirements, calibrating an RF monitor can also be cost-effective. If the monitor is only used for non-critical measurements, calibrating at longer intervals can save money. Additionally, calibrating a monitor can help extend its lifespan, further reducing costs.

Peace of Mind

Finally, calibration provides peace of mind. Knowing that the RF monitor is within specification and providing accurate readings can boost confidence in the data and decisions made based on those readings.

In summary, calibrating an RF monitor is about more than just accuracy. It ensures consistency, safety, and cost-effectiveness while providing peace of mind to the users. The frequency of calibration will depend on various factors, including the usage, environment, and industry standards, but the benefits of calibration are clear.

Monitoring Contractions: Tracking Time and Distance for Expectant Mothers

You may want to see also

What factors affect how often I should calibrate my RF monitor?

Several factors affect how often you should calibrate your RF monitor. Here are some considerations:

Manufacturer Recommendations

Firstly, it's essential to refer to the manufacturer's recommendations for calibration intervals. These specifications are typically outlined in the product manual and are designed to ensure optimal performance and accuracy. Adhering to these guidelines is a good starting point for maintaining the precision of your RF monitor.

Usage Patterns and Environment

The frequency of calibration also depends on how you use your RF monitor and the environment in which it is used. If your monitor is frequently transported between locations or subjected to knocks, bumps, or varying temperatures, it will likely require more frequent calibration. Establishing a fixed calibration schedule and observing how the monitor responds is a practical approach. You can then adjust the calibration frequency accordingly.

Criticality of Measurements

The nature of your measurements also influences the calibration interval. If you rely on highly accurate readings for critical projects or applications, more frequent calibration is advisable. This is especially true if your work involves adhering to industry standards, safety regulations, or quality assurance (QA) requirements. Calibration before and after critical projects is crucial to ensure the reliability of your results.

Performance and Drift

Monitoring the performance of your RF monitor over time is essential. As equipment ages, you may notice drift in readings, indicating the need for more frequent calibration. By reviewing calibration trends and year-over-year results, you can make informed decisions about calibration intervals. If you observe significant changes or deviations from standards, you may need to calibrate more often.

Industry Standards and Regulations

Compliance with industry standards and regulations is another factor influencing calibration frequency. Some industries, such as pharmaceuticals, may have stringent requirements for calibration before, during, and after critical projects. Additionally, certain industries or applications may mandate annual or periodic calibration to maintain the integrity of measurements and adhere to safety protocols.

In summary, a combination of manufacturer recommendations, usage patterns, criticality of measurements, performance drift, and industry standards will help determine the optimal calibration frequency for your RF monitor. By considering these factors, you can ensure the accuracy, reliability, and consistency of your RF monitor's readings.

Does Your Monitor Have FreeSync? Here's How to Tell

You may want to see also

What are the risks of not calibrating my RF monitor often enough?

While there are no explicit risks outlined for RF monitors, there are general risks associated with not calibrating digital monitoring devices often enough. These risks can be applied to RF monitors by assuming that a lack of calibration will result in inaccurate readings.

The primary risk of not calibrating any device, including RF monitors, is the potential for inaccurate readings and measurements. Over time, digital monitoring instruments can become unstable and may record data that deviates from industry standards or defined specifications. This instability can lead to several issues, such as decreased productivity, higher costs, and lower product quality. For example, if an RF monitor is not calibrated correctly, it may provide false readings, leading to incorrect assumptions about the RF environment, which could have safety implications for workers.

Another risk of not calibrating RF monitors often enough is the potential for compromised safety. This is especially critical in industries such as food and pharmaceuticals, where precise temperature and humidity measurements are essential to maintain product safety. If an RF monitor is not accurately calibrated, it may fail to detect hazardous levels of RF radiation or provide false readings, leading to potential health risks for workers exposed to these conditions.

Additionally, not calibrating RF monitors frequently can lead to dissatisfied customers and brand damage. Inaccurate readings can result in lower product quality, as issues may go undetected. This can lead to customers receiving products that do not meet their expectations, damaging the brand's reputation and resulting in a loss of market share and profits.

Furthermore, irregular calibration of RF monitors can result in increased wastage and inventory losses. If the recorded data is incorrect due to calibration issues, businesses may inadvertently spoil products due to inadequate storage or processing conditions. This can lead to costly waste and inventory losses, impacting the business's bottom line.

To mitigate these risks, it is generally recommended to calibrate digital monitoring devices regularly. For RF monitors, manufacturers typically suggest a functional calibration or recertification every two years. However, for instruments used outdoors or in construction/climbing environments, an annual check is advised. Additionally, users should perform a function test on their RF monitor before each day's work to ensure accurate readings.

By following these calibration guidelines, businesses can minimize the risks associated with inaccurate measurements and maintain the reliability and accuracy of their RF monitoring equipment.

Monitoring Data Usage: Arris Router Guide

You may want to see also

Frequently asked questions

Most manufacturers recommend a functional calibration or recertification every two years. This is computed from the date of first use or the date of the calibration certificate included in the original purchase.

LBA Group, a company that provides RF asset solutions, recommends an annual check for instruments used outdoors or in construction/climbing environments. They also advise a function test by the user before each day's work.

To ensure accuracy, you should calibrate your monitor(s) every 2-6 weeks.

If you work in an environment where your test equipment is transported throughout your facility or to other facilities, or if your equipment is subjected to bumps, knocks, and falls, you should establish an annual or semi-annual calibration schedule.