Chocolate is one of the most popular foods in the world, with a history dating back thousands of years. The process of making chocolate is intricate and involves several steps, from harvesting cacao pods to tempering and moulding the final product. In this video, we will take you through the journey of how chocolate is made, from the tree to the bar. We will also explore the different types of chocolate, such as dark, milk, and white chocolate, and the various techniques used to create them. Finally, we will put our knowledge to the test by attempting to make a chocolate replica of a camera, showcasing the creativity and versatility of this beloved treat.

| Characteristics | Values |

|---|---|

| Camera model | Vintage Nikon SLR |

| Material | Luxury Italian chocolate |

| Taste | Velvety smooth with a naturally creamy taste |

| Shelf life | 6 months |

| Price | £35 (~$44) |

What You'll Learn

Cacao tree to chocolate bar

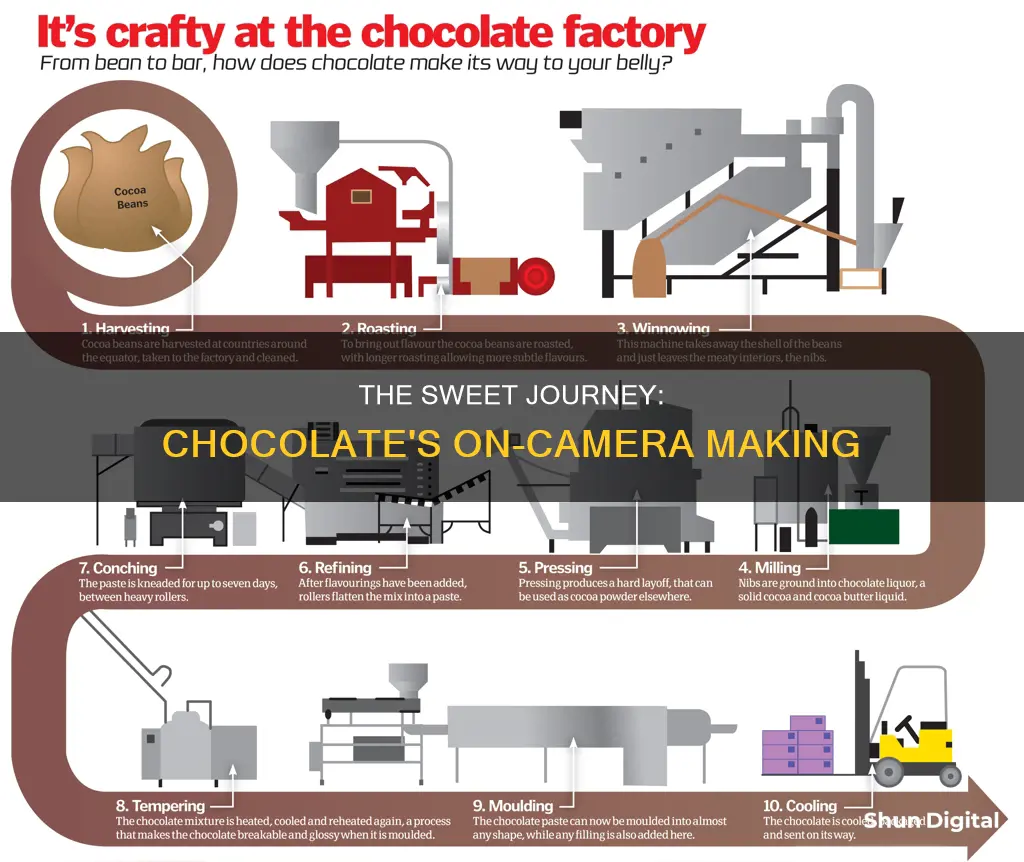

Harvesting

The cacao tree, formally known as Theobroma cacao, grows within 20° north and south of the Equator and thrives in hot temperatures, rain, and shade. The cacao tree bears oval fruits, or pods, which are about 5–12 inches long. Each pod contains 30–50 seeds, known as cacao (or cocoa) beans. The pods are ripe when they turn a vibrant yellow or orange colour and are harvested twice per year, though they can be harvested continually.

Farmers use sharp knives or machetes to cut the ripe pods from the tree, being careful not to damage the tree. The pods are then opened, and the seeds are removed. Each seed is about the size of an olive and is surrounded by a white pulp or pith.

Fermentation

Beans are cleaned by hand, with the pulp left on to help develop flavour. Exposed to light, the cream-coloured beans turn purple. They are then ready for fermentation, which can be done via the "heap method", popular in Africa, or using a system of cascading boxes, favoured in Latin America. In both methods, the beans are covered with banana leaves and left to ferment for 2 to 9 days. During this time, the beans begin to take on the colour and flavour of chocolate.

Drying

After fermentation, the beans must be carefully dried to a low moisture level of around 7%. They are placed in the sun for 7 to 14 days and are continually turned over to ensure consistent drying. In some areas with high humidity, fire is used to finish drying the beans. Once dried, the beans are graded, packed into sacks, and shipped to chocolate makers.

Roasting

Once received by the chocolate maker, the beans are inspected, cleaned, and then roasted. Roasting takes less than an hour and helps to develop the flavour of the chocolate. Like coffee beans, cacao beans can have a light, medium, or dark roast. Roasting also loosens the beans' natural shells.

Winnowing

After roasting, the beans must be cracked and have their shells removed. The shells are very thin, so once the beans are cracked, they can be put into a winnowing machine. The winnower blows air under the beans, separating the lighter shells from the heavier beans. The shells are referred to as "husks", and the broken pieces of beans are called "nibs".

Refining & Conching

The nibs are then reheated and ground down into a paste called cocoa mass or cocoa liquor. This paste is placed under extremely high pressure to yield two products: cocoa powder and cocoa butter. Sugar and other ingredients are added during this stage, depending on the type of chocolate being made.

The next step is conching, a careful process of rolling, kneading, heating, and aerating the chocolate. A conche is a large agitator that stirs and smooths the mixture under heat. This step is important for producing consistent, pure, and delicious chocolate, as it defines the final aroma and flavour.

Tempering

Before being made into bars, the chocolate must be tempered. Tempering is the process of heating, cooling, and then reheating the chocolate to stabilize the fat molecules and give the chocolate a shiny surface, a strong snap, and a smooth texture.

Moulding & Packaging

The final step is moulding the chocolate into bars. The tempered chocolate is poured into moulds and tapped against a tabletop to release air bubbles. The bars are then left to cool and set before being packaged.

Extending Camera Battery Life: Tips for Longer Shoots

You may want to see also

Fermentation and drying

Fermentation is the first step in transforming the cocoa beans into chocolate. The cocoa beans are placed in wooden boxes and covered with banana leaves to maintain a high temperature. During this process, the beans' sugars are broken down, and the beans lose about half their weight. The fermentation process also helps to develop the flavour of the beans, as it causes the formation of chocolate flavour precursors within each bean. The length of fermentation depends on the type of bean and the climate, but it usually takes between two and seven days.

Following fermentation, the beans are laid out to dry. This process usually takes between five and ten days, during which the beans are placed on wooden boards or bamboo mats and are turned over and raked to ensure consistent drying. The beans are then graded, packed into sacks, and shipped. If the beans are not dried properly, mould can form during shipment, and the flavour of the beans becomes very acidic and unpalatable. Therefore, drying is a critical step in flavour development.

Unlocking the S7 Edge: Exploring Camera Modes

You may want to see also

Grinding and blending

The nibs, which contain about 53% cocoa butter, pass through refining mills and are ground between large grinding stones or heavy steel discs, creating a cocoa paste. The paste is then subjected to hydraulic pressure, and the cocoa butter that flows out is a pure and valuable fat with a marked aroma. After filtering and purifying, it looks very much like ordinary butter.

The cocoa butter has important functions. It not only forms part of every recipe, but it also gives the chocolate its fine structure, beautiful lustre, and delicate, attractive glaze. The heat generated by grinding causes the cocoa butter or fat to melt and form a fine paste or liquid known as chocolate "liquor". When this liquid is poured into moulds and allowed to solidify, the resulting cakes are unsweetened or bitter chocolate.

The grinding process can be done in a wet grinding machine or melanger, which has a bowl containing rotating granite rollers and a granite slab that are motorized. The friction caused by the rotating stones generates heat, which evaporates the sharp-tasting volatiles and develops the texture and viscosity of the cocoa.

The first grind of the beans is usually done in a milling or grinding machine such as a melangeur. The nibs are ground or crushed to liquefy the cocoa butter and produce what is now called chocolate liquor or chocolate liquid.

For the second refining process, most chocolate manufacturers use a roll refiner or ball mill, which has two functions: to further reduce the particle size of the cocoa mass and to distribute the cocoa butter evenly throughout the mass, coating all the particles.

The rolling process itself creates heat that melts and distributes the cocoa butter. The flavour of the chocolate and the particle size are then decided upon by the manufacturer. Different percentages of cocoa butter are removed or added to the chocolate liquor. Cocoa butter carries the flavour of the chocolate and produces a cooling effect on your tongue that you might notice when eating dark chocolate.

The grinding process can be a long one, requiring patience as it could take up to an hour. It is important not to grind the nibs below fifteen microns, as this will make the chocolate too viscous.

BestBuy's Camera Restocking Fee: Why the Extra Charge?

You may want to see also

Conching and refining

Conching

Conching is a crucial step in chocolate manufacturing that was invented in 1879 by Rodolphe Lindt. It is a mechanical process that refines chocolate and gives it a smooth, homogeneous texture. The name comes from the Spanish word "concha", meaning shell, as the original vessel used to hold the chocolate was shaped like a conch shell.

During conching, the chocolate is heated and mixed while undergoing mechanical shear forces. This process can take anywhere from 2 to 78 hours, depending on the type of chocolate and the desired flavour profile. The conching process achieves several objectives:

- Texture development: Conching helps create a smooth and velvety texture by reducing the particle size of cocoa solids and sugar crystals.

- Flavour enhancement: Conching develops the desired flavour profile by allowing volatile flavours to evaporate and promoting the interaction between cocoa solids and cocoa butter.

- Moisture removal: Residual moisture in the chocolate is evaporated during conching, improving the shelf life and stability of the product.

- Chemical and physical changes: Conching promotes chemical reactions such as oxidation and reduction processes, further refining the flavour and colour of the chocolate. It also reduces the acidity of cocoa and improves its pH.

Refining

Refining is the final grinding process that ensures all particles in the liquid chocolate are extremely fine, resulting in a smooth texture with no detectable grit. The goal is to achieve a particle size of around 20-30 microns, as the human tongue loses its ability to determine texture and grittiness at this size.

While conching and refining are separate processes, they can sometimes occur at the same time. Modern machinery, such as the melangeur and refiner/conche, can combine both processes into one. The first period is the refining stage, during which the conching effect occurs simultaneously due to the heat generated from the grinding action of the machine. The chocolate then continues to be mixed, agitated, and heated until the final flavour is achieved.

Syncing Camera Raw: A Step-by-Step Guide

You may want to see also

Tempering and moulding

Tempering is the process that creates the desired crystalline structure in the solid chocolate, which is essential to achieve the desired qualities in the finished chocolate. This includes a high melting point so that the chocolate melts in your mouth but not in your hands, an attractive glossy finish, and stability.

Chocolate, or more specifically the cocoa butter in the chocolate, is polymorphic. This means that when liquid chocolate crystallizes (solidifies), it may do so in several different ways depending on how it is cooled. Cocoa butter contains many different kinds of fat, so several possible crystal forms can develop during solidification. Only one of these possible crystal forms, known as Form IV or Form V, has the qualities desired in chocolate.

When tempering chocolate, tiny solid crystals (or "seeds") are established in the liquid chocolate mass by lowering the temperature of the finished liquid chocolate to about 85°F (or 82-85°F) while continuously mixing. This seeding temperature ensures that relatively small crystals are formed, which are desired to create a fine-grained solid chocolate with a snap. After allowing seeding to occur, the liquid chocolate's temperature is raised to about 90°F (or 86-90°F) to melt out any unwanted seeds, i.e. crystals with the wrong shape that may have also formed. At this temperature, the desired crystals do not melt, but the other crystal forms do, melting away back into a liquid. The liquid chocolate is now tempered and will remain tempered as long as the temperature remains about 90°F and mixing continues.

There are several methods for tempering chocolate, including the seeding method, using a microwave, and using cocoa butter beta crystals. The seeding method involves melting 2/3 of the chocolate in a double boiler or bain-marie to a temperature of around 115°F (or 100-110°F), stirring often, and then gradually adding the remaining chocolate to bring the temperature down to 84°F (or 82-85°F). The chocolate is then briefly reheated by placing the bowl back over the double boiler for 5 to 10 seconds at a time, stirring, until it reaches 89°F, which is the "working temperature".

The microwave method is similar, but the chocolate is melted in a microwave-safe bowl in 30-second intervals on high, stirring in between, until it reaches a temperature of 100-110°F. The remaining chocolate is then added in small amounts while stirring. The chocolate will thicken and become cool, shiny, and smooth as it is continuously stirred and "seeded". When it has reached the range of 84-91°F, the chocolate is tempered and ready to be used.

Cocoa butter beta crystals can also be used to temper chocolate. This method involves melting 2/3 of the chocolate to a temperature of 115°F and then adding the remaining 1/3 of the chocolate back into the melted chocolate to cool it down. At 96°F, 1% beta crystals (1 teaspoon per 7 ounces of chocolate) are added, and the mixture is stirred well. The chocolate is then cooled to 79°F and then warmed to 86-90°F for workability.

Once the chocolate has been tempered, it can be poured into clean, dry moulds. A large syringe or a spatula can be used to dispense the chocolate into the moulds. The moulds can then be given a few gentle but firm raps on the counter to smooth out the chocolate. The chocolate can be refrigerated, frozen, or left at room temperature to harden before unmoulding.

Charging a Fuji X-30: A Quick Guide to Powering Up

You may want to see also