LCD monitors are found in most laptop computers and flat-panel monitors. They are made of two pieces of polarized glass that contain a liquid crystal material between them. The liquid crystal material is made of electrically charged molecules that can block or allow light to pass through. Each crystal is charged with an electric current and manoeuvred to form specific patterns that result in the images that appear on the screen.

LCD monitors also contain a backlight, which creates light that passes through the first substrate. The electrical currents cause the liquid crystal molecules to align, allowing varying levels of light to pass through to the second substrate and create the colours and images that you see.

What You'll Learn

LED backlights

LED-backlit LCDs have several benefits over CCFL-backlit LCDs. Firstly, they offer a wider colour gamut and a greater contrast ratio, resulting in more vibrant and detailed images. Additionally, LED backlights are significantly lighter and cooler, and they consume 20-30% less power, leading to longer battery life for portable devices. The slim design of LED-backlit LCDs, with some screens being less than 0.5 inches thin, makes them ideal for use in a variety of devices, including ATMs, digital billboards, mobile devices, and more.

While LED backlights offer improved image quality and energy efficiency, they do have some limitations. One issue is that LED-backlit LCDs cannot achieve true blacks for pixels due to the backlight still allowing some light through even when pixels are in the "off" state. This can result in a "blooming" or "halo" effect on dark pixels. Additionally, the local dimming method used in LED backlighting to increase contrast can lead to a loss of detail in small, bright objects on a dark background.

Overall, LED backlights have revolutionized the LCD monitor industry by providing enhanced image quality, improved energy efficiency, and a more compact design. These advancements have made LED-backlit LCDs a popular choice for a wide range of applications, contributing to their widespread adoption in modern display technologies.

HP Pavilion 27xi Monitor: Size and Specifications

You may want to see also

Liquid crystals

The liquid crystal layer is sandwiched between two sheets of polarized glass, which act as filters. The first sheet of polarized glass allows vertical light waves to pass through, while the second sheet blocks or filters out horizontal light waves, as these would distort the image. The liquid crystals are influenced by electrical currents, which cause them to align in specific patterns and allow varying levels of light to pass through, creating the colours and images we see.

The liquid crystal layer is made up of molecules that are able to change their orientation under the influence of electricity. This change in orientation affects the properties of the light beam passing through them, creating a connection between the increase in electric voltage and the change in the orientation of the crystal molecules, which is essential for image creation.

The liquid crystal layer is illuminated by a backlight, which can be provided by fluorescent lighting or LED lighting. This backlight passes through the first sheet of polarized glass, then through the layer of liquid crystals, and finally through the second sheet of polarized glass, allowing the user to view the image.

The unique properties of liquid crystals, which allow them to manipulate light while being affected by electrical currents, make them a crucial component in the functioning of LCD monitors.

Assembling the Acer LCD Monitor CB281HK: A Step-by-Step Guide

You may want to see also

Transparent conductive screen layers

The transparent conductive layers are responsible for ensuring that the electric current reaches every pixel. This is achieved without causing any visible interference on the screen. The transparency of these layers is vital as it prevents any obstruction to the light passing through the other layers of the LCD monitor.

Indium tin oxide (ITO) is often used as the transparent conductive material in LCD screens. It is a key component in maintaining the optimal performance of the monitor. ITO is a type of transparent conductive oxide that exhibits both high electrical conductivity and high optical transparency. This unique combination of properties makes it ideal for use in LCD screens.

The use of transparent conductive screen layers in LCD monitors is a significant advancement in display technology. By utilising these layers, LCD monitors can provide clear and uninterrupted images to the user. This technology has contributed to the widespread adoption of LCD screens in various devices, including computers, laptops, smartphones, and televisions.

In summary, transparent conductive screen layers play a critical role in the functioning of LCD monitors. Made from materials like indium, these layers enable the flow of electric current to each pixel without causing any visible interference. This technology enhances the user experience by delivering uninterrupted and high-quality visuals.

Charging Your ASUS Portable Monitor: A Step-by-Step Guide

You may want to see also

Reflector sheet

A reflector sheet is a component of LCD monitors that aids in enhancing the display's visibility by making use of natural light. It is particularly useful in devices without a backlight, such as calculators, speedometers, and the Nintendo Game & Watch.

The reflector sheet is a part of the LCD reflective film, which is a linear polarizer. This film consists of a polarizing layer and a reflective layer, typically made of silver or silver aluminium. The reflective layer is positioned at the back of the LCD, enabling it to reflect sunlight or ambient light. This reflected light illuminates the LCD screen, making it clearly visible even without a dedicated backlight.

The LCD reflective film is designed to adhere to the back of the LCD screen. Its reflective properties allow it to redirect light towards the screen, enhancing its brightness and improving the overall display quality. This is particularly advantageous in situations where external lighting conditions are less than ideal, such as in bright sunlight or dimly lit environments.

The reflector sheet, as part of the LCD reflective film, plays a crucial role in ensuring the functionality and usability of LCD monitors and displays, especially in devices where a backlight is not feasible or desired. By utilising natural light, the reflector sheet helps reduce power consumption and improve the energy efficiency of the device. Additionally, the reflector sheet contributes to the overall durability of the LCD monitor by eliminating the need for a dedicated light source, which may be more prone to failure or burn-out over time.

Monitoring Tomcat Memory Usage: A Comprehensive Guide

You may want to see also

Light guide plate

A light guide plate is a key component in the backlighting of LCD screens. It is a thin, clear, fiber-optic sheet that is illuminated by a bar of LEDs from the edge of the screen. The light guide plate is responsible for taking internally reflected light from the edge and releasing it in a controlled fashion along the surface, so that the front of the screen is evenly lit.

The light guide plate is part of a multi-layered structure in LCD screens. From back to front, the layers are: a thin reflective backing layer, a polarizing layer, a liquid crystal layer, a diffuser layer, and the light guide plate.

The light guide plate is made from either acrylic or polycarbonate. It can be flat or slightly wedge-shaped, with the angle of the wedge helping to distribute light more evenly. The surface of the plate is marked with a pattern of dots, which act as escape points for the light to exit. The diffuser layer then diffuses the illuminated light from this pattern, creating a uniform light source.

The working principle of the light guide plate is based on the total reflection of light at the interface of a transparent plate. When light rays hit the surface boundary at less than a certain angle (the critical angle), they will exit the plate immediately. However, light rays hitting the surface at angles greater than or equal to the critical angle will be totally internally reflected. By etching the surface of the plate, we can create locations where the internally reflected light rays can scatter and exit the plate at specific locations.

LCD light guide plate technology was first invented by the Japanese company Mingtuo in 1986. It is also known as edge light and is the mainstream method of notebook computer LCD backlight lighting. This lighting method is widely used in devices such as notebook computers and digital cameras, which require the use of large-area LCDs.

LCD Monitor Lifespan: Degradation and Longevity Explored

You may want to see also

Frequently asked questions

An LCD monitor is a thin, light computer monitor that displays images through the use of a liquid crystal display. LCD screens are found in most laptop computers as well as in flat-panel monitors.

LCD monitors use two pieces of polarized glass (also called substrate) that contain a liquid crystal material between them. A backlight creates light that passes through the first substrate. Meanwhile, electrical currents cause the liquid crystal molecules to align to allow varying levels of light to pass through to the second substrate, creating the colours and images that appear on the screen.

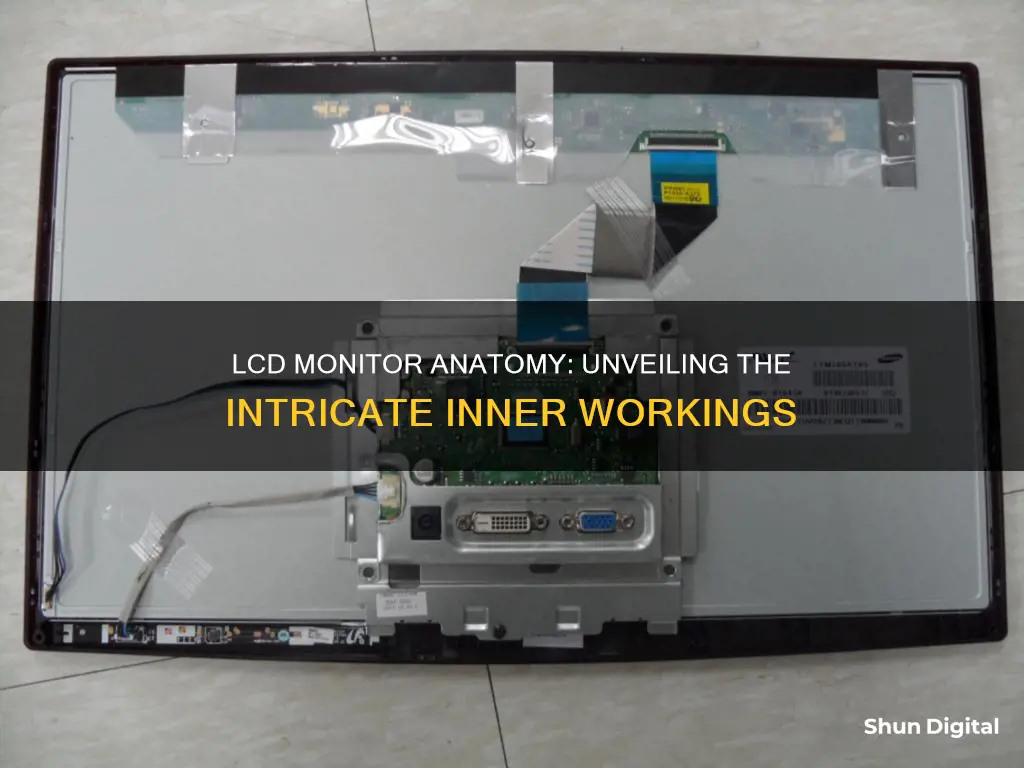

The components of an LCD monitor include:

- An LED backlight

- Liquid crystals

- Transparent conductive screen layers

- Reflector sheet

- Light guide plate

- Diffuser sheets

- Prism sheet

- Polarized glass sheet

- Glass substrate (backplane)

- Power supply and common electrode